Exploring the history of Seikado and testing out the most prized Japanese cookware in existence. If you’re interested in an extremely in-depth breakdown of prices and material, check out our substack. The price comparisons versus Duparquet and Soy Turkey were accurate at time of writing but may no longer be as the price of silver fluctuates.

If you’ve been a long time follower of this site, you’ll know that we love a good story behind niche and rare cookware so when we happened to be in Kyoto to visit the latest Noma pop-up, it was the perfect opportunity to do something we never thought would be possible.

Along Kyoto’s Teramachi Street (not the covered arcade) lies a small quaint storefront with an artisanal workshop and gallery located round the back called Seikado. Currently run by 7th generation pewterer and owner Genbei Yamanaka (山中源兵衛), Seikado is not a cookware store, but instead specialises in the making of religious artifacts that are still used in shrines and temples all around Kyoto today. In fact, the name Teramachi (寺町) roughly translates to ‘temple district’, where Toyotomi Hideyoshi ordered a large number of Buddhist temples to be moved there around the year 1590, and thus Seikado was born in the year 1838 in order to meet the concentrated demand of religious artifacts and teaware.

Today, they still continue to make the same items from a variety of materials like tin, copper, brass and silver, including elaborately engraved teapots and canisters, sakeware as well as a select few pieces of homeware like chopstick rests, trays, plates and containers. However, if specially requested with a production time of around 3 months, they are able to produce custom works, including pure solid silver cookware. To us, this was extremely surprising as silver is actually a comparatively soft metal compared to other metals, and runs a much higher risk of deforming or getting scratched. To compensate, once the pot has been formed into shape, the craftsman at Seikado meticulously hand hammers the entire pot, creating thousands of tiny indentations that strengthen the silver and contribute to its aesthetic. In our case, we were lucky enough to see a pure silver 30cm sukiyaki pan being made, carefully hand hammered over many hours. The client at the time was given the option to have the pot made between 1.2mm to 3mm in thickness, with the latter being only 1.5 times more expensive. The shop themselves recommended the 3mm thickness as it aligns with the specifications of high quality French cookware. At the same time, Seikado had also requested a woodworker friend to make a matching beautifully handmade Japanese paulownia wood box for only an additional fee of 15000 yen, along with a calligraphy inscription.

What are the benefits of silver cookware?

If you consider traditional copper cookware’s claim to fame, and why it was so ubiquitous in many of the most famous French kitchens of the past, it’s that it has high heat conductivity, allowing you to not only cook evenly, but also exercise an extremely precise level of heat control. Because not only does it heat up quickly, it also loses heat quickly, meaning that the moment you take the pan off the stove, it won’t continue to overcook your food. However, copper has its downsides, not only does food stick directly to it, cooking acidic foods directly on copper can cause it to leach into your food, causing copper poisoning. To counteract these issues, copper cookware has been traditionally lined with tin which is food safe and extremely non-stick (with the exception of cookware designated for sugar work that is pure unlined copper). Unfortunately, tin also has its downsides, with a melting point of 231.9°C well within the range of temperatures achieved during normal cooking. This means that if you preheat your tin-lined cookware empty, or try and crank up the heat to smoke point to sear a steak, you risk melting the tin and ruining your pan. It’s soft nature also means that you don’t want to be using metal utensils on your tin-lined cookware, as you risk exposing the copper underneath. Alternatively, you can find the modern invention of stainless steel lined copper cookware, but stainless steel is not as non-stick as tin, and also has a lower heat conductivity which offsets why you’d use copper to begin with.

And here’s where solid silver cookware takes the top spot. Heralded as not only having the highest heat conductivity over copper (even higher than gold too), it also has the non-stick properties of tin but a much higher melting point of almost 961.8°C. This means that unlike tin-lined copperware that cannot be pre-heated empty due to the danger of the tin melting, you can crank up the heat all the way to smoke point as you would a cast-iron pan and obtain a perfect sear. Not only that, there’s a reason why silver is the metal of choice for medical and surgical instruments- it is naturally antibacterial and food safe. That means you don’t have to line silver cookware with anything. And while using metal utensils to cook in it might scratch it, it’s basically indestructible as there isn’t anything under the silver than more silver.

A review of solid silver cookware

So when we were given the chance to use this pot in our recipe testing for 4 weeks, we just had to jump at the chance. In anticipation, we prepared silicon cooking utensils and soft sponges in order to not scratch or damage the pot. However, we were immediately surprised that whilst perfectly polished, the pot already has quite a number of scratches on it. We were unsure whether these scratches were unavoidable as part of the manufacturing process but just had to accept them.

Testing if it’s genuine pure silver

Now first of all, as much as we’d like to simply trust Seikado given their history and reputation, as well as the lower incidences of precious metal scams in Japan compared to overseas (looking at your Dubai, Thailand and Perth Mint), we just had to get it tested. So we brought it to an independent auctioneer with an XRF gun to analyse the entire pot including the 30 different spots on the body, all 8 rivets and 2 handles. For those unfamiliar, an XRF gun works by exposing the metal to X-rays which cause the metal atoms to emit their own X-rays with individual energy levels that allow the metal to be identified. In this case, all the tests came back as 99.9 purity of silver, which is as good as one might expect for precious metals.

Silver’s non-stick qualities

When cooking, immediately the trait that stood out the most to us when using the pan wasn’t the heat conductivity, but its non-stick qualities. Now it wouldn’t be fair to say that the silver we were using was more non-stick than your teflon pans, but it was on par with tin lined pans in our opinion. That means you’d still need to add a little oil when frying eggs, or allow the meat you’re searing to caramelize a bit with some rendered fat before flipping it for it to be really non-stick. Its non-stick qualities did feel a lot more natural however, with most bits of food coming off with just a little bit of pushing or stirring. We’d always felt as though the teflon non-stick quality to be a little unnatural in the way a fried egg can just slip off without any further additions, before taking into account the potential health and environment implications of forever chemicals. The fact that we didn’t need to worry about scraping off bits of teflon while using the pan was definitely an advantage and washing it was definitely a breeze.

For many of the French copper pots that we use in our kitchen, we usually find it quite difficult to wash around the rivets, especially if we do cooking that involves a lot of caramelisation and whilst we had the same issue here, it wasn’t any serious enough that a soft toothbrush wouldn’t clean.

Silver’s heat conductivity and heat retention

How about the traits that everyone always raves about? Well here we were a little conflicted at the end of our testing in the same way we felt about the gunmetal tempura pot, which is that at 3.5kg weight and 3mm thickness, the pan actually contains quite a substantial amount of silver and since the heat required to raise the temperature of an object not only involves its specific heat capacity and conductivity, but also weight (𝐽/𝑔*°𝐶), it actually took a while for it to heat up, even after we sourced a gas burner size that was appropriate for a 30cm pan. We’d argue that a cheap non-stick pan made from thin aluminium brought from the supermarket easily heated up faster, but of course that isn’t a fair comparison. When compared to cast iron pans and copper pots of similar dimensions and weights, it heated up and cooled down much faster and more importantly, could do so whilst still maintaining its high temperature. The problem with cheaper thin cookware or copper pots is that the temperature drops too quickly when searing a large piece of meat, something that didn’t happen with the silver pot. We’d go as far as to say that it performed even better than cast iron skillets at searing meat, whilst also coming up to smoke point temperatures way faster.

Downsides of Silver Cookware

Interestingly, there can be too much of a good thing and with the ingrained force of habit in us used to heating cast iron pans for a long time to sear steaks, it’s easier than you think to heat the silver pan up to temperatures that will just immediately burn the steak upon contact. Also the solid silver handles? They get INCREDIBLY hot, we’d reckon due to the high heat conductivity, probably about as hot as the pan itself. Furthermore, despite care being taken to not damage the pan, silver is ultimately a soft metal and it was ultimately the point of contact between the pot and the iron grill of the stove that scratched the pan the most, something that was very hard to avoid as the pan inadvertently moved around during cooking.

Even heating and Silver Cookware

Where the silver pan did stand out above the rest of the competition in a way we didn’t expect was how even it cooked. While that may sound really trivial, we’re serious when we said we were absolutely blown away, from searing cubes of bacon, making french toast or frying tempura, the evenness was just surreal, even compared to tin-lined copper. Whilst we couldn’t verify it for sure, we think that it had to do with both the silver’s innate properties, but also the fact that it was a heavy 3mm pan, giving it enough of a heat reservoir to do so.

Testing with Damaging Foods

So on to the heavy testing, kimchi, eggs and tomatoes. Instantly, frying eggs in the pan caused it to darken. Eggs, especially the whites, contain sulfur-containing amino acids such as cysteine and methionine. When eggs are heated, these amino acids decompose and release hydrogen sulfide gas (H₂S), which forms silver sulfide (Ag₂S), which is the blackish tarnish on the pan. Surprisingly, the effect on the taste of the eggs was relatively unnoticeable, and with enough oil preheated in the pan, it was possible to reduce the tarnishing to barely noticeable. If we were to wash the pan immediately after cooking, there would be no visible marks leftover.

How about the 3 hour simmered kimchi stew and tomato sauces? We expected some tarnishing with the sulfur from the garlic and onions in the kimchi, but we found that with both the kimchi and tomatoes, it was the acidity that caused some changes, some dulling of the shiny metal and darkening in colour. Whilst silver is considered fairly resistant to acid, in the presence of chloride ions from the salt in the kimchi, an insoluble layer of silver chloride can form that is dark in colour.

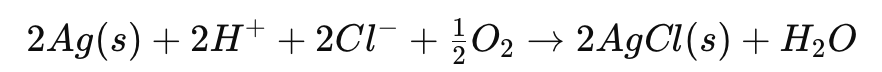

This is due to how chloride ions can react with silver ions of any form, to produce AgCl, which is insoluble and removes Ag⁺ from equilibrium. This shifts the electrochemical balance, promoting more silver oxidation (Flashback to Le Chatelier’s principle if you remember your high school chemistry!). The surface reaction can be represented as:

Again it didn’t have any effect taste wise, though it wouldn’t be something I’d want to do constantly as it strips away a small amount of silver from the pot each time, as well as silver chloride not being exactly safe to consume.

So how does it compare to the price of other silver cookware?

Now if you’ve been around the internet for a while you’ve probably heard of producers of silver cookware like Duparquet in the US, or Soy Türkiye in Turkey, often selling their cookware at exorbitant prices, typically 400% to 700% mark up on the price of pure silver. We’ve done a deep-dive into exact price calculations in our substack, however in short, Seikado’s pricing easily beats all the competition. When they manufacture silver cookware, Soy also hand hammers their cookware to strengthen it, made possible by the low labour cost in Turkey. However, as Seikado also hammers their pots, and has a higher labour cost than Turkey, we don’t think their 700% mark up is justifiable, before considering they use copper handles compared to Seikado’s pure silver handles. At Duparquet, they instead use sterling silver, an alloy typically composed of 92.5% silver and 7.5% copper, meaning that you get an even worse bang for your buck. So whilst the premium is lower at 480%, we still don’t think it’s worth it, before taking into account that they use cast iron handles. After our calculations, we were even more shocked that Seikado only charges a mark up of around 300%, making it even more worth it to buy compared to jewellery, whilst arguably requiring more skill, work and man hours. Of course at the end of the day you’re still buying a piece of cookware and so if you’re looking for an equivalent investment for money, you still can’t beat pure silver bullion, coins or bars that have premiums as low as 102% of melt price. Find out more at our substack.