This article follows on from what is tempura and is part of our tempura series.

The best flour for tempura

As traditional Japanese tempura batter only consists of water, eggs and flour, the specific qualities of each of these ingredients are extremely important. From our intensive testing that has been carried out, we have come to the conclusion that of these three ingredients, it is the selection of flour that has one of the greatest impacts on your final tempura. Therefore, we wanted to dive deep into what sort of flour you should be looking for when trying to make tempura.

In a tempura batter, the flour used has the greatest influence over the final texture of the batter. As the batter primarily serves as the textural complement to the burst of flavor from the actual tempura ingredients themselves, the batter itself tends to be fairly subtle in flavor with maybe a light hint of umami and aroma absorbed from the frying oil. Therefore, the customary flour used for making tempura batter is your standard neutral flavored wheat flour. Other flours such as rye, buckwheat, and semolina etc are almost never used due to their coarser texture and more pronounced taste.

What type of wheat flour is best for tempura?

Within the category of wheat flour, the first rule of thumb when trying to choose flour for high quality tempura is to only use white flour. Whole-wheat or wholemeal flour, which uses every part of the wheat berry including the germ and bran, makes a tempura batter that has a rough and mealy mouthfeel. As this is undesirable, white flour is used exclusively when making tempura. Unfortunately, this also means that the germ and bran, which contains the majority of nutrients in a wheat berry, has been removed.

How does the gluten network develop in tempura batter?

In order to understand the type of wheat flour that is ideal for making tempura, we need to start with a simple primer on the role of gluten in flour. Beginning with a simple misconception, dry wheat flour does not contain any gluten. Instead, wheat flour contains two proteins, glutenin and gliadin. However, when water is added to the flour (in other words, the flour is hydrated), a chemical process begins whereby glutenin and gliadin proteins bind together to produce gluten. Therefore, it’s more precise to talk about a flour’s gluten potential, that is, the amount of gluten it has the potential to form when hydrated.

As the chemical process of gluten formation continues, the glutenin proteins start to link with each other via disulfide bonds, giving the batter elastic strength and stretching qualities. Meanwhile, the gliadin proteins increases the batter’s stretching and extending abilities. This process is continuously occurring, but progresses at a moderately slow pace (think minutes and hours instead of seconds). Simultaneously, proteases naturally present in the flour start acting on the gluten, breaking them down into smaller segments that, interestingly enough, relink with each other and form additional connections.

The process of breaking down the gluten strands by naturally occurring proteases, followed by the natural relinking of the gluten strands repeats by itself over and over again, giving rise to the formation of a web-like network of gluten. The rate of development of this gluten network can be significantly increased by mixing or agitating the batter mixture, but will continue if left to its own devices, albeit at a much slower rate.

It is this gluten network that gives the batter its elastic and extensible characteristics. As an example, it is the gluten network present in bread dough that allows it to expand and capture the carbon dioxide produced by the yeast, giving us the characteristic holes found in bread. The elastic nature of the gluten allows the dough to expand without tearing, whilst the extensible nature of gluten gives it the strength to maintain its shape after expanding and not collapse during baking.

There are a few key takeaways from the information above:

- Gluten development starts when water is added to flour, and will continue even if not mixed.

- Mixing increases the rate of gluten development

- Gluten development does not stop even when mixing stops

- The development of the gluten network gives batter and doughs their elastic and extensible characteristics.

Why is gluten development in tempura important?

The gluten development in a batter or dough, or the lack thereof, gives many of the foods we encounter daily their characteristic taste. When making pies, tarts and shortbread cookies, having as little gluten development as possible is paramount to obtain a crumbly and melt in your mouth texture. Too much gluten development and your cookies will be hard and chewy.

The opposite is true for bread and pasta. A well developed gluten network is what gives bread their characteristic chewy texture, while also allowing pasta dough to be rolled thin and stretch out into long strands without tearing or breaking apart, giving them that sought after al-dente texture when bitten into. If too little gluten development is achieved, bread dough will collapse in the oven when baked, whilst noodles will fall apart when boiled, becoming soft and mushy.

Unfortunately for us, great tempura batter lies not at either ends of the gluten development spectrum, but somewhere in between, within a goldilocks zone that tempura chefs are forever striving to stay within.

If too much gluten development occurs, there are two usual resulting scenarios:

- your tempura batter may still be crispy straight out of the fryer, but will quickly become soggy by the time it’s served to your guest.

- Your tempura batter is hard and crunchy rather than lightly and crispy, much like the crust you’d find on fish and chips rather than tempura.

The opposite end of the spectrum, where too little gluten development occurs, is more subtle yet still noticeable. Your resulting tempura might still be light, crispy and airy but once you bite into it you’ll realize that the batter doesn’t melt in your mouth. Instead, the batter is slightly jagged and brittle, shattering in your mouth as though there is no structure.

What is the ideal amount of gluten development in tempura batter?

Instead, if the ideal amount of gluten development in your batter is achieved, the resulting tempura will have thin sheets or flakes of batter surrounding the ingredients. The flakes should be thin enough to let light through, yet strong enough to withstand being fished out of the oil without breaking. It is these laces of tempura batter that should be delicately crispy at the first bite, before lightly melting away in your mouth.

What is the ideal flour protein content for tempura batter?

Managing gluten in your tempura batter arguably ties with oil temperature control as the most important and hardest part of tempura making. Whilst there are different additives you can incorporate into your batter and different techniques to utilize when managing gluten development in your tempura batter, the easiest way to get it right from the very start is to simply choose a flour with an appropriate amount of protein to begin with.

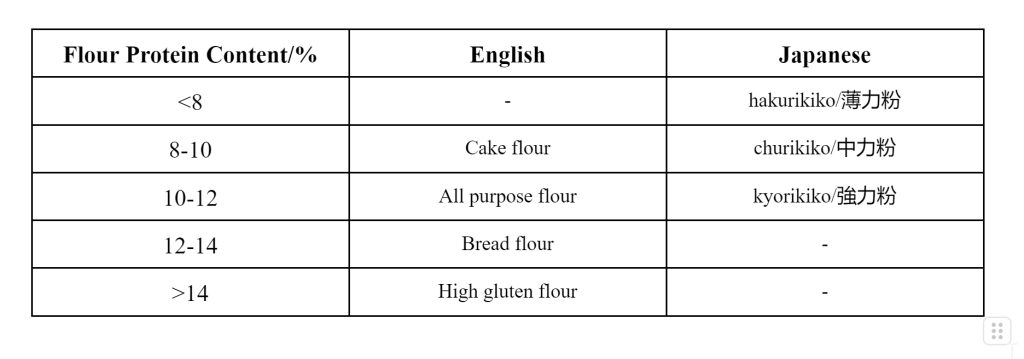

When looking at wheat flour strengths, they’re usually sorted based on their protein content, for example:

- Cake flour or pastry flour with 8-10% protein

- All purpose flour with 10-12% protein

- Bread flour with 11-14% protein

- High gluten flour with ~14% protein

Interestingly enough, the protein content of a flour does not tell with absolute certainty how much gluten will develop when the flour is hydrated. This is because the protein in the flour consists of both water soluble and water insoluble proteins. Both glutenin and gliadin, which bind together to form gluten, are the main water insoluble proteins present in wheat flour. However, the protein content of flour is also made up of soluble proteins such as globulins and albumins which do not contribute to gluten formation. Therefore, as the protein content of flour increases, the gluten potential of the flour may not increase proportionately; it is merely an increase in soluble proteins. Nonetheless, as we do not have more accurate means to assess flour gluten potential, we simply use flour protein content as an approximation for how gluten it will produce when hydrated.

In Japan, the three grades of flour you can typically find in a supermarket are:

- low protein flour (hakurikiko/薄力粉) of around 6.5-8.5% protein that is used for cakes

- medium protein flour (churikiko/中力粉/小麦粉) of around 8.5-10.5% protein that is used as an all-purpose flour

- high protein flour (kyorikiko/強力粉) for anything above 11.5% protein for ramen noodles and bread.

Low protein flour (hakurikiko/薄力粉) is the go to grade of flour that is used for tempura making.

When comparing flour protein content in Japan compared to the English speaking world, what immediately jumps out at you is how much lower protein content Japanese flours contain, even for the same category. For example, cake flour in Japan can be as low as 6.5% protein versus 8% protein in the west. This is partly due to cultural preferences surrounding desirable textures in food. When you think of Japanese milk bread, cheesecake or strawberry cake, they’re all renowned for the light, airy and fluffy texture which are in part due to the flour’s low protein content.

In terms of tempura, that means we can straight off the bat rule out using bread flour or high gluten flour for tempura batter. This results in batters with too much gluten development which, as mentioned above, yield hard and soggy tempura. From our testing, all purpose flour also tends to yield mediocre results without the use of certain additives, which leaves us with cake flour.

Cake flour is used exhaustively by all tempura chefs in Japan, from specialist establishments all the way to street side stores. The low protein content of cake flour allows chefs to precisely control the consistency of their tempura batter through the amount of whisking or the amount of flour added, allowing them to fine tune the amount of gluten network development without going overboard. After many attempts, we haven’t been able to find a perfect substitute for cake flour found in Japan due to a variety of reasons (elaborated below). However, having done trials in several countries with different cake flours available, we can confidently conclude that it is possible to find cake flour that will yield the desired textures in your tempura, even if the protein content is a little higher than what is found in Japan.

How is low protein cake flour different in Japan?

When you first open a bag of Japanese cake flour, what strikes you immediately is the almost perfectly snowy white color of the flour, followed by how soft and finely textured the flour feels when you run your fingers through it. When used to make cakes, the cakes have a softer texture, more volume, and a brighter color. When used to make tempura, the batter has a delicate crunch to it, before melting away. Whilst we are not experts on the subjects of grain milling and flour manufacturing, we wanted to provide you with our thoughts on what makes Japanese flour different.

Ash content

The ash content of flour refers to the mineral content of flour. The ash content of a flour is measured by incinerating the flour in a furnace and then expressing the remaining minerals as a percentage of the original weight of the flour.

Why is ash content important?

The majority of minerals found in a grain of wheat is located in the germ, husk or bran, with the endosperm containing relatively little. As a comparison, whole wheat flour, which is made from the endosperm, germ and bran, contains around 1.5-2.5% ash. In contrast, pure endosperm is around 0.3-0.35% ash. While the final ash content of the flour is also affect by a variety of factors such as how the type of wheat as well as how it was cultivated, knowing the ash content of your flour is important as it gives us an indication of how well has the bran and husk been separated from the endosperm during the manufacturing of white flour.

As mentioned above, white flour is desirable when making tempura as flours that contain more germ and bran cause the batter to have a rougher and more mealy mouthfeel. As a case study, let’s look at Japan’s Nisshin Super Violet cake flour, which is arguably the most widely used tempura flour in Japan by chefs and home cooks alike. This flour has an ash content of 0.33%, making it basically close to pure endosperm.

Outside of Japan, as artisanal baking has become more and more fashionable, the trend has been to move toward white flours with a higher ash content of around 0.50% and thus it’s more difficult to source flour with the same ash content unless you can find a specialty supplier. Most places around the world have their own system for grading flour by ash content so we highly recommend looking it up for where you live.

On a different note, it’s important to note that ash content measures the mineral content of the flour and not the protein content. This means that when you’re sourcing flour for tempura, you cannot simply look for flour with a low ash content as it may have a high protein content. You need to look for low protein flour with a low ash content as well.

The relationship between flour particle size and color

As mentioned above, cake flour from Japan seemed to have an especially fine grained texture and bright white color. As it turns out, there may be a correlation between these two characteristics. If you were to shine a light on a smooth mirror compared to a jagged and crooked mirror, you’d expect the smooth mirror to shine brighter as it reflects more light back to you. The crooked mirror will reflect some of the light in different directions and thus shine less brightly. A similar phenomenon can be found in flour, with a small flour particle size acting like a smooth mirror, whilst larger particle sizes, with a larger surface area for crevices to occur, acting like a jagged and crooked mirror. Therefore, white flour with a smaller particle size should in theory appear more bright and white to the naked eye, thus explaining why we perceive Japanese cake flour to be snowy white with a smooth texture.

In terms of particle size, there are a myriad of factors that affect this characteristic such as wheat quality and milling technology. Almost all aspects of the flour milling process affects particle size, from the sifter sieve opening to the types of rolls and their adjustments. This means that the type of flour available to us consumers will be driven by the current trends in commercial baking that influence the decision of flour manufacturers. Unfortunately for us, the kind of cakes and desserts prized in Japan and Asia that emphasize a soft light and fluffy texture are not valued in the west and thus manufacturers have no incentive to manufacture flours that meet these specifications. This unfortunately means that other than importing flour directly from Japan, we have little control over the choice of flour available to us. If flour from Japan is not available, our personal recommendation to you is to check out your local asian supermarket for cake flours from China or other south-east asian countries that also value the same textural characteristics in their cakes and desserts as Japan. These flours tend to meet the requirements of having a low protein content, low ash content and fine particle size.